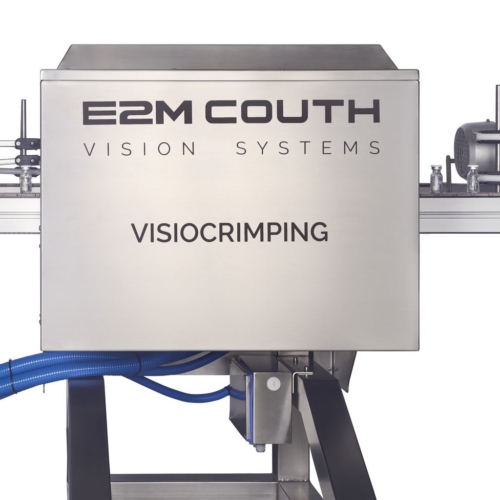

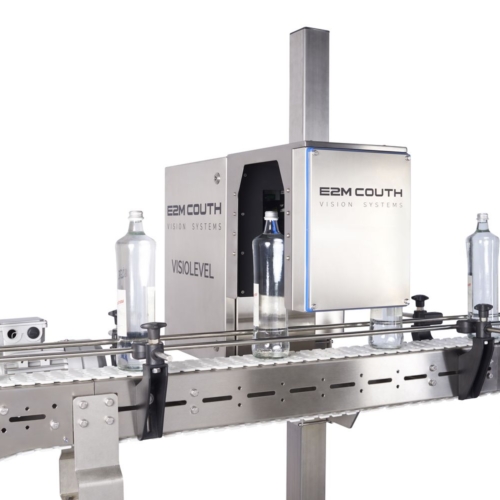

Vision Systems

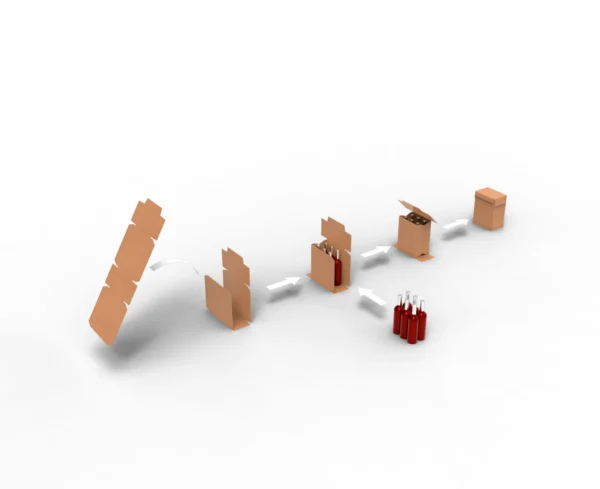

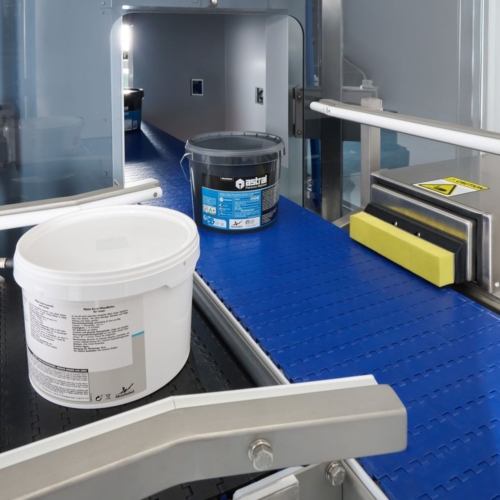

Vision inspection systems are pivotal tools in modern manufacturing and quality control processes. Utilizing advanced imaging technology, these systems enable automated inspection of products for defects, ensuring that only items meeting strict quality standards reach consumers.

This technology is crucial across numerous industries, from electronics and automotive manufacturing to pharmaceuticals and food packaging.

Benefits Of Artificial Vision Systems

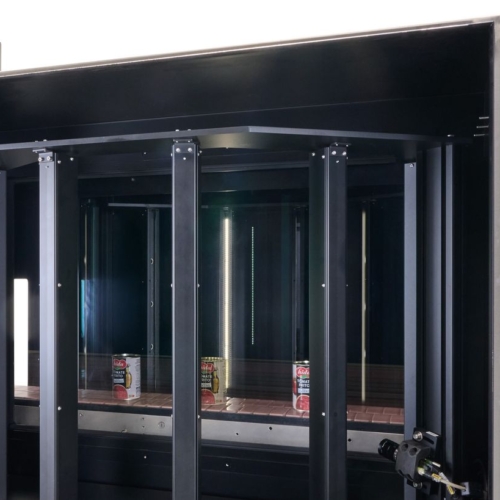

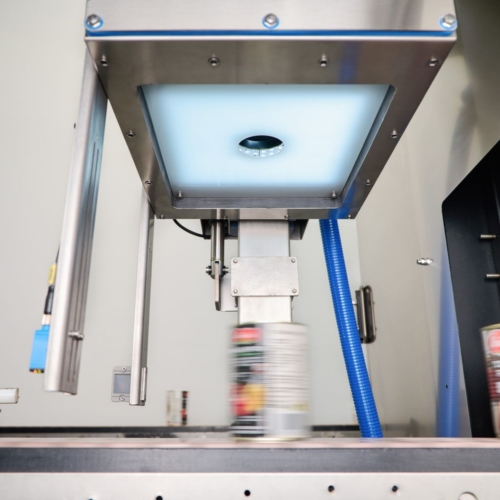

The implementation of E2M COUTH’s vision systems offer a number of benefits for companies and industries. These systems not only eliminate all quality control problems in the packaging process, but also allow you to see how production quality improves. Below are some of the ways a company can benefit from installing these systems:

- They allow product quality to be increased, thanks to their detailed and precise inspection by the machines.

- They increase productivity, because these systems can assess where and how problems occur so they can be fixed.

- They allow a more precise quality control process. This means no high margin of error, as can be the case due to the visual limitations of operators.

- Industries can reduce their low-quality costs. By increasing productivity and reducing losses, companies will be able to make better use of all their resources.

- Achieving consistency and meeting all final product quality standards allows all consumer needs and expectations to be met. This is beneficial for future purchases they may make.