Highly effective train drying, even in sub-zero temperatures

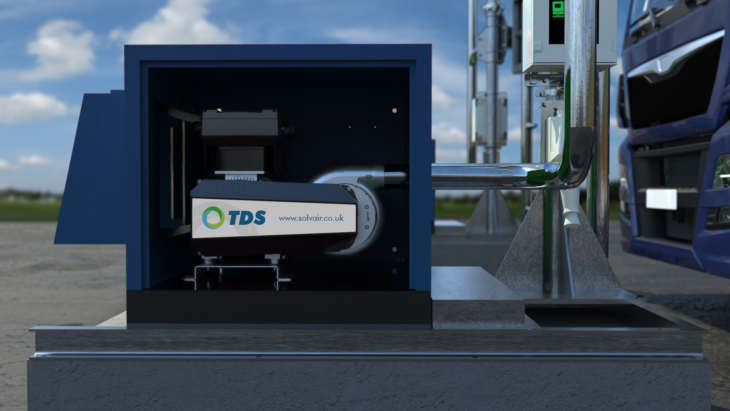

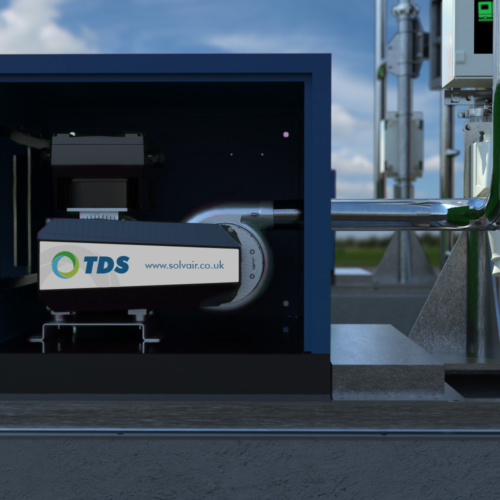

The SolvAir Train Drying System is a powerful Air Knife blow-off solution, positioned at the exit point of a train carriage washing station. Integrating seamlessly with the train washing system, it can fully remove water from the surface of passing trains and carriages.

Powerful, yet compact and energy-efficient

The drying system is driven by two AT1200 15kW centrifugal blowers. These industry-leading devices are highly efficient and designed specifically for drying and blow-off applications. The result is a compact yet powerful drying system that delivers exceptional energy efficiency.

Even with substantial amounts of water on the surface of the train as it exits the wash station, the system effectively removes moisture using the powerful airstream from its series of Air Nozzles. Trains departing the system are cleaned and dried without risk of icing and/or water staining.

- Easy to install and run, designed to result in no disruption to business or on-site operations.

- Fully automatic, energy-saving, and requires no additional resources such as heating or manpower.

- Environmentally friendly train drying systems