Air Knives are highly effective tools, used in manufacturing, for a wide variety of applications and purposes including cleaning, drying, blow-off and liquid control.

Air Knives are an integral part of Air Knife Systems. Highly effective for cleaning, drying, blow-off and liquid control for a wide range of industrial applications, Air Knives are designed to ensure a perfectly optimised air flow for a range of industrial applications.

Air Knives are a vital part of the production line for many industries, such as those that work in food and beverage, industrial and electronic, automotive and aerospace, and rubber and plastics.

The effectiveness of Air Knives is achieved through precision engineering and design - Air Knives are engineered to produce a curtain-like flow of air that not only covers the full shape of an object, but acts as a barrier to foreign matter as well.

Air Knives direct pressurized air onto the surface of objects, usually as they move along a conveyor belt. They provide essential applications at various stages of production, such as cleaning, cooling, drying or quality checking, and to prepare objects for their final dispatch.

Air Knives create a sheet of uniform air that can adhere to object surfaces (the “Coandă Effect”). This makes them ideal for drying objects, as they are effective at removing moisture from surfaces where liquid has been used at an earlier stage of the manufacturing process. Air Knives are particularly effective at drying as their air streams are able to completely cover the surface area of an object, including hard to reach places.

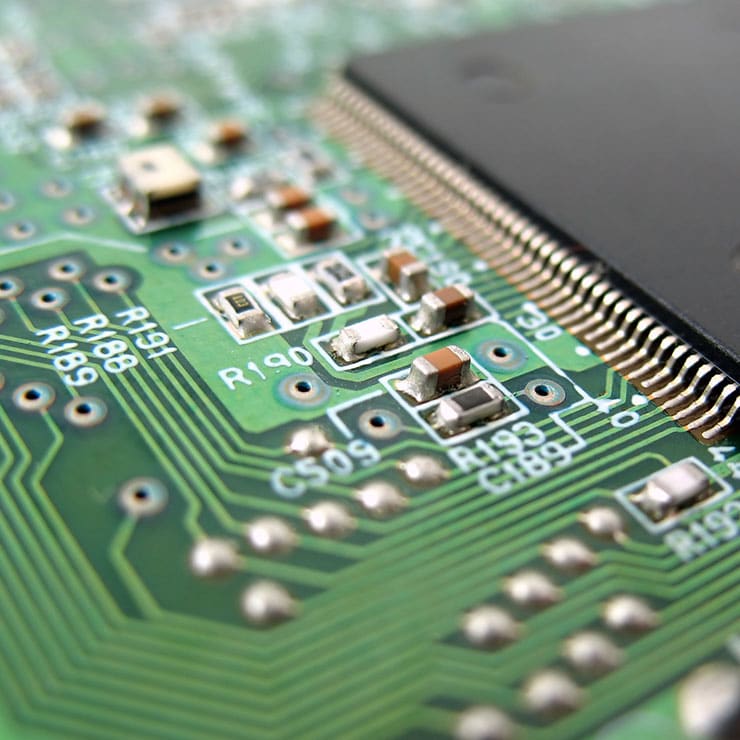

The airstream emitted from Air Knives is high intensity, meaning it is a highly effective means of removing dust, dirt, debris and liquid from the surface of objects, without corroding or damaging the object. This is particularly crucial where the quality of the final product, such as with items manufactured in the electronics industry, is crucial to their success.

As well as being powerful enough to remove or control foreign substances on surfaces, Air Knives are also able to create sterile environments that objects can pass through. Air Knives come in a range of configurations, and for example can cover a wide area where their airstream creates a uniform sheet of air, or an “air curtain” which protects objects from dust and particles.

Ionized Air Blower Systems also not only remove particulates, dust and contaminants, but they also prevent these contaminations from returning and adhering to the object’s surface through their ionized airflow.

Air Knife Systems are often used to cool objects, for example as they exit high heat environments, such as ovens. These systems are suitable in situations where for example liquid cooling is not desirable, and where the object is needed to be cooled rapidly.

There are several main types of Air Knives, depending on the shape or material required for the application that they will be used for.

Air Knives made from aluminium provide a long life-span whilst also ensuring a sterile output for air. They are lightweight and versatile, and are available in a range of shapes and sizes.

Stainless Steel Air Knives are suitable for harsh industrial environments where increased strength and heavy-duty use is needed. They are used for example where environments are corrosive.

Circular Air Knives provide 360° adjustable airflows, and are suitable for applications that involve cables, tubing or plastic/rubber lines.

When multiple air streams are needed, Cone Manifolds provide a series of air outlets. They are used for example in applications that deal with objects across a range of sizes and shapes, as well as those where the air stream must cover a greater distance.

More about Cone Manifolds

Spyder Manifolds are used for applications where objects have complex shapes and hard to reach areas that need to be dealt with. Their arms can be positioned as required for any object.

Air Nozzles are used when small air amplifiers are needed. They are fully adjustable and can be locked into position as needed.

Used to control the rate of air flow, speed, direction and shape of the ejected air. These are the smallest air amplifiers available.

Air Knives are highly adaptable, easy to maintain, and low cost to run. This means they are now widely utilised across a range of industries, and provide the most effective and competitive system available for a wide range of key applications.

Air Knives are used in the food and drink industry for bottling, packaging, canning and pouch applications. This includes a range of uses, from assisting with labelling, to evenly distributing coatings, to drying after washing/rinsing or hot melt labelling.

Air Knives used by food and drink manufacturers are able to clean, dry and blow-off objects without corrosion, for example under lids which is a potential problem point with water or oil-based systems.

As well as this, they prevent contamination, as well as ice build-up, and so can guarantee hygienic performance. Air Knives constructed from FDA compliant 304 Stainless Steel are food safe.

Air Knives come in a range of materials and configurations, making them suitable for heavy industry, as well as delicate medical and electronic parts.

Industrial and Electronic manufacturers use Air Devices to spot dry, all-over dry, remove debris including cleaning agents/oils/sealants, vacuum hold-down of fabrics/metal sheets/wood, and pneumatic conveying/sorting of plastic parts. For example, Air Knives are able to create a hold down force to assist in the mechanical bonding of materials to surfaces. As well as this they are used for static elimination and cleaning exterior/interiors of objects prior to coating or painting.

Air Knife systems come in a range of scales, from circular that can dry rubber/plastic extrusions, to large-scale set ups that can clean whole trucks. They are also able to control the thickness of liquids, for example when coatings on objects are needed.

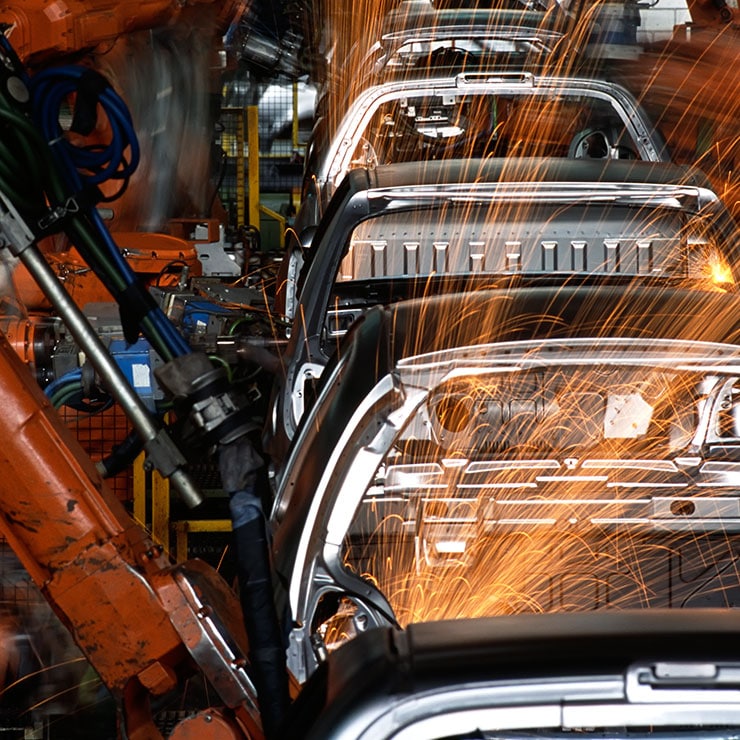

Air Knives are typically used in the automotive and aerospace industries for a range of applications, including drying, cleaning and blow-off pre-treatment for paint finishes, and removing coolant emulsion and swarf during the machining process. They are also able to remove static from plastic bumpers, fascia, wheels, windscreens and mirrors.

Air Knives are able to deliver clean, dry, oil-free air, making them highly useful to the rubber and plastics industry. The types of applications they are commonly used for include coating wire, blowing-off oils, sealants, chemicals and debris, and preparing objects for pre-packing.

As extrusion lines are commonplace for rubber and plastics manufacturers, Air Knives are also often used to remove water droplets following liquid cooling.

The list of uses for Air Knives is substantial - from poultry to circuit boards, engine blocks to extrusion lines. Their adaptability and ability to be extremely powerful, without damaging products, and with energy and cost saving in comparison to water based or compressed air systems, is what makes Air Knife Systems an essential part of the manufacturing process.

If you would like any more information on our Air Knives, or if you would like us to test an Air Knife System on your site to see if you can improve productivity and reduce costs, please contact us.

Our team of specialists will contact you within 24 hours to discuss your requirements and arrange your full in-depth consultation free of charge.

Air Knife Systems use a precision-engineered linear slot to direct and utilise high-velocity air from a centrifugal blower. They are amazingly versatile and are used for a wide variety of applications in manufacturing.

Their adaptability, speed and efficient set up means they can increase the rate at which production lines can run, whilst maintaining excellent performance, and decreasing energy costs.