An Air Knife System is a system designed and engineered to create air jets suitable for industrial purposes. Air Knife Systems use Air Knives that have precision-engineered linear slots to direct and utilise high-velocity air generated by a centrifugal blower. Air Knife Systems are highly effective at cleaning, drying, blow-off and liquid control for a wide range of applications.

Air is blasted through the air knife slots via a high-speed centrifugal blower to deliver the predetermined exit air volume and velocity needed. Electrical currents from anti-static bars can also be injected into the exit air knife stream to neutralize the static electricity charge on some surfaces.

Air Knives are often the most energy-efficient and effective method of removing or controlling foreign substances for any surface. Most Air Knives are stationary with products passing through them on a conveyor however there are also systems where the product is stationery and the Air Knives move around it. The potential that Air Knives provide for many different kinds of industries is therefore enormous.

An industrial Air Knife is a pressurized air plenum chamber with a continuous slot through which pressurised air exits in a laminar (uniform) flow pattern. The exit air velocity creates an impact air velocity onto the surface of products that the air is directed toward. Read how air knives work

Air Knife Systems are typically installed onto existing production lines and can vary in size, shape and scope to produce airstreams that fit a wide range of products sizes, shapes and line configurations.

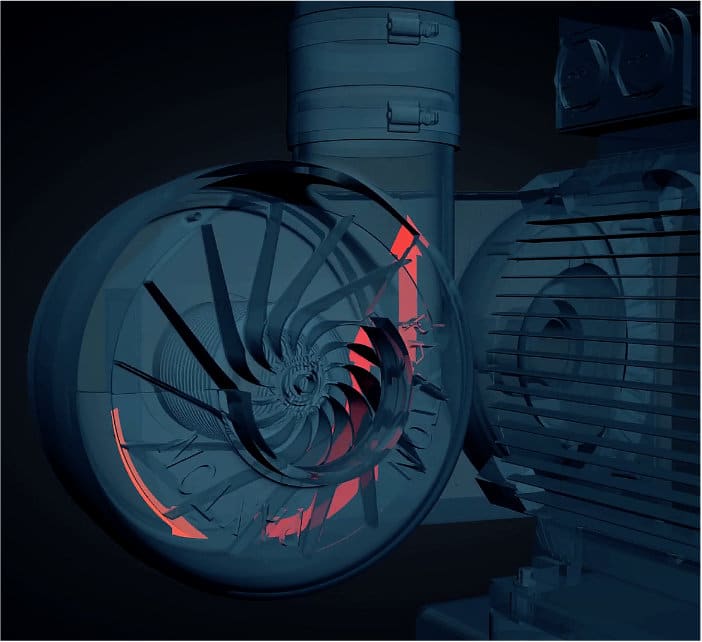

High speed, high performance centrifugal blowers to generate pressurised air.

The pressurised air is then delivered through the connecting pipework, to the Air Knives or Devices.

The Air Knives and Devices are arranged so that they give maximum effect (cooling, drying, cleaning) to the object passing through it.

Air Knife Systems can be controlled via remote control panels and adjusted using variable frequency drives (VFDs) offering complete flexibility and energy efficiency.

Our team of specialists have decades of experience in providing innovative air solutions and will contact you within 24 hours to discuss your requirements and arrange your full in-depth consultation free of charge.

Air Knife Systems self-generate air delivery from high performance, centrifugal blowers. Centrifugal blowers are capable of generating a continuous flow of air, which is then ejected through carefully selected Air Devices.

Air Devices provide the mechanism by which the powerful airstream generated by centrifugal blowers is distributed. Air Devices are made up of Air Knives, or Nozzle Manifolds, where several Air Knives are combined.

The powerful stream of air that is ejected from Air Devices is delivered from the blower to the Air Knives by connecting pipework. This pipework is designed to ensure the air remains pressurised, no matter how the Air Devices are mounted.

Air Devices can be arranged to clean, dry or blow-off any sized or shaped objects through configuration of mounting kits. Mounting kits ensure that Air Knife Systems are able to perform effectively without human intervention, thereby enabling contactless operation 24 hours a day.

Our Air Knife Systems are highly optimised to ensure maximum effectiveness at minimum running costs. Often, the system blower is coupled with a Variable Frequency Drive (VFD) unit. VFDs provide users with maximum control of the energy usage, based on their particular production rates and specific package sizes.

Constructed for industrial applications we offer a number of robust blower enclosures which provide a wide range of benefits, including blower protection from harsh, corrosive and wet environments whilst providing significant sound abatement.

The Air Knives used in an Air Knife System usually range from 100 to 3048 mm (4 to 120 inches) in length with a discharge air slot ranging from 0.40 to 2.0mm (0.015 to 0.08 inches). A stationary air knife configuration can require from one to ten or more air knives, depending on the application criteria. Air is blasted through the air knife slots via a high speed centrifugal blower to deliver the predetermined exit air volume and velocity needed. Electrical currents from anti-static bars can also be injected into the exit air knife stream to neutralize the static electricity charge on some surfaces.

The exit air velocity from an Air Knife System creates an impact air velocity onto the surface of whatever product the air is directed to. This impact air velocity can range from a gentle breeze to greater than Mach 0.6 = 454 mph = 731 kph = 40,000 fpm = 203 m/sec. Therefore an air knife alters the surface of a product without mechanical contact.

Blowers are machines used in manufacturing that provide a large flow of air or gas through rotating blades.

SolvAir use Paxton High Performance Centrifugal Blowers. These deliver unparalleled efficiency and reliability for demanding industrial and process applications.

When incorporated into a well designed Air Knife System, centrifugal blowers are capable of producing air flows to 2,500 cubic metres per hour and pressure to 250 millibar.

The Air Blowers used in SolvAir’s Air Knife Systems are different to standard Compressed Air systems.

With the increase in the range of applications that Air Knife Systems are used for, innovative designs have emerged around the Air Knives themselves. Several different types of Air Device are now available:

Suitable for a wide range of industrial environments, providing ‘precision’ air flows, as well as a long life-span. Used mainly in drying processes, these have adjustable slot widths for optimum power and diffusion.

Provide high-quality performance in corrosive and/or sanitary environments. Constructed from FDA Compliant 304 Stainless Steel they are ideal for Food, beverage and pharmaceutical industry applications.

Suitable for cable or tube drying and plastics or rubber extrusion lines, where they effectively remove water after cooling baths. Fully controllable 360° adjustable performance ensures no dead spots.

Suitable for a wide range of industrial environments, providing ‘precision’ air flows, as well as a long life-span. Used mainly in drying processes, these have adjustable slot widths for optimum power and diffusion.

Available in various sizes and combine inline nozzles with “spider-like” arms that can flex to any position, allowing for the air streams to access hard to reach places. Our Syder Manifolds can be custom built as needed, ensuring the flexi arms are sized and spaced as required.

Used to control the rate of air flow, speed, direction and shape of the ejected air. These are the smallest air amplifiers available. Our SV10 Air Nozzles and Manifolds are fully-adjustable round nozzles that can be locked into the desired position.

Our team of specialists have decades of experience in providing innovative air solutions and will contact you within 24 hours to discuss your requirements and arrange your full in-depth consultation free of charge.