TBOS provices an easy way for transport and logistics companies to reduce the risk of plastic pellet leaks into the environment and meet OCS guidelines and commitments.

OCS compliance – why it's important for the transport industry

If you run lorries or tankers that carry nurdles, it's important to fulfil your environmental responsibilities. And that means having a reliable plastic pellet clean-up system that supports the aims of the Operation Clean Sweep® programme.

Nurdles are vital to the production of the plastics we use in our day-to-day lives. However, when they go astray they can become an environmental hazard, polluting our rivers, seas and oceans and threatening wildlife.

What is Operation Clean Sweep®?

Driven by the plastics industry, Operation Clean Sweep® (OCS) is a campaign dedicated to helping every plastic resin handling operation achieve zero loss of plastic into the environment. It's supported by the British Plastics Federation and PlasticsEurope.

The risk plastic poses to the environment is an issue that's relevant to all participants in the supply chain, from resin producers to plastics manufacturers. However, the risk is highest in the transport and logistics sector. Nurdles or plastic pellets can easily leak from packaging during transportation or handling.

That's why OCS compliance is so important for any company involved in the shipping of nurdles. Having a robust system in place for clean-up of spills is a key part of following best practice and supporting OCS.

How does OCS compliance work?

The key message at the heart of the OCS campaign is that good handling practice can reduce plastic pellet loss. The OCS manual provides practical solutions to prevent loss for those who make, ship and use nurdles.

Companies who sign up to the OCS Pledge to Prevent Resin Loss promise to improve their set-up and operations to prevent and deal with spills. The manual provides guidance on how to carry out an audit to identify areas where pellet emissions are most likely to happen, as well as advice on actions to mitigate risk, such as staff training, supplying spill kits and catch trays in areas where pellets are transferred or improving filters in drains.

Over the last 25 years, hundreds of companies across the world have committed to the OCS Pledge. However, this is just a small percentage of the plastics industry as a whole and there needs to be more widespread adoption of the OCS principles to significantly reduce the environmental impact. According to the OECD's Global Plastics Outlook, significant stocks of plastics have already accumulated in aquatic environments, with 109 million tonnes of plastics in rivers and 30 million tonnes in the ocean.

A simple plastic pellet (nurdle) solution for hauliers!

There's an easy way for transport and logistics companies to reduce the risk of plastic pellet leaks into the environment.

TBOS (Truck Blow Off System)

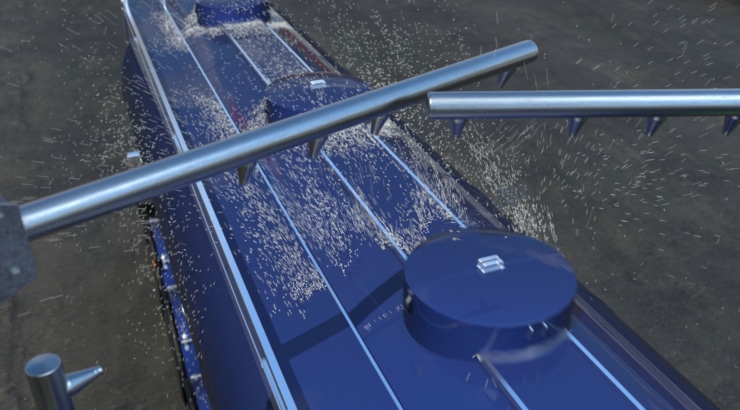

SolvAir's Truck Blow-Off System (TBOS) is a unique, market-leading solution for plastic pellet removal and pellet cleaning for trucks and tankers. Fully automatic and energy saving, the system removes 90+% of plastic pellets and is easy to install, with minimal operational or logistical disruption.

You can read more about TBOS and how it can help you meet OCS compliance here.

A new standard

PAS 510:2021 is the world's first plastic pellet loss prevention standard. It provides standardised protocols for the handling of pellets, flakes and powders throughout the supply chain, covering organisational responsibilities, leadership, training and operational controls.

Sign up for OCS compliance

If your company is part of the plastics supply chain, such a haulage company, you have a responsibility to ensure that plastic pellets, flakes and powders are contained and cannot escape into the environment. The British Plastics Federation now accepts OCS sign-ups from both member and non-member organisations. You can sign up online to OCS here.