Air-Knife Manufacturing Solutions

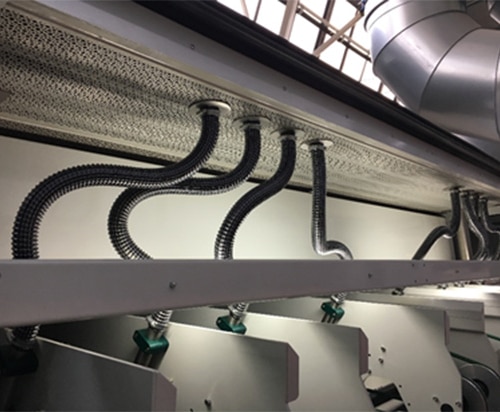

Air Knife Systems provide fast cleaning, cooling, drying and blow-off applications for manufacturers. The energy-efficient, industry-leading 3 year warranty blowers generate high velocity air flows that are effective whilst using 80% less air than compressed air systems.

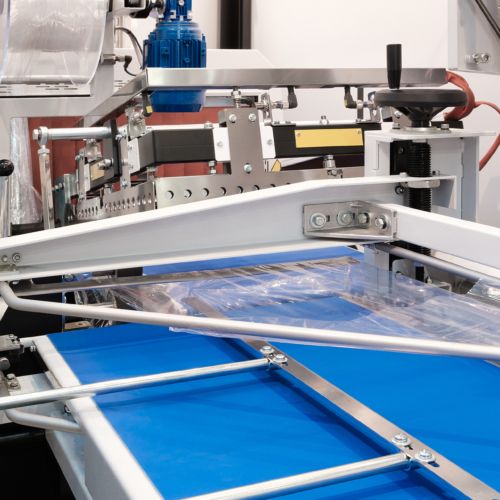

Air Knife Systems come in a range of sizes and are suitable for processing large-scale, complex and multi-material objects, for example with applications for pre- and post-paint work, removal of metal/wood/oil/powder debris, and vacuum hold-downs for fabric sheets.

Air Knife Systems Benefits for Manufacturing Production Lines

Air Knife Systems provide a full range of benefits for manufacturing production lines, including:

- Generates highly controllable, high-velocity, clean oil-free air

- Pneumatic conveying and sorting of plastic parts, plastic caps, small metal parts, or other components

- Drying after painting, coating, shrink labeling

- Effective and quick drying prior to coding, marking, painting or coating

- Removes 99% of debris, metal/wood shavings, dust/powder cleaners, oils

- Fast drying after painting, coating and labelling

- Removes static electricity from interior/exterior of objects and metal sheets

- Vacuum hold-down for example with fabrics, wood and metal sheets

- Cost saving compared to compressed air and large blowers

- Minimise downtime waiting between cooling, drying and labelling

See typical products & use-case applications

Easy integration bringing increased production & reduce costs

Air Knife Systems are highly effective drying, cleaning and blow-off systems meaning that objects are fully prepared for coding, marking, painting or coating. This minimises spoiled goods and downtime on the production line.

Investment paybacks are often achieved in just a few months, sometimes in a matter of weeks, providing a superior return-on-investment.

Contact us to discuss your specfic requirements