Prevent moisture contamination and corrosion

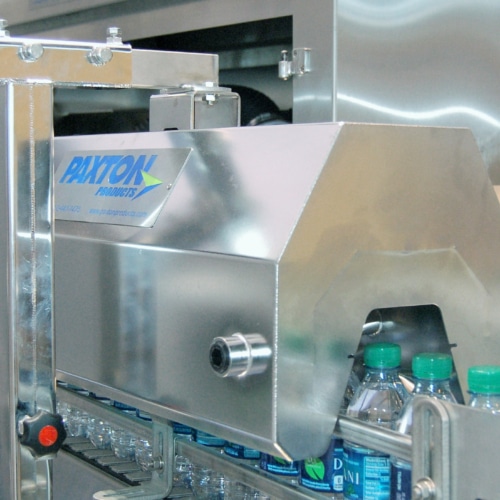

Air Knife Systems provide beverage manufacturers with a highly effective air flow solution that completely removes surface moisture from the surface of objects.

The high-velocity laminar air flow generated by our FDA Compliant 304 Stainless Steel air knives and manifolds is suitable for harsh, corrosive, wash-down or sanitary environments, and powerful enough to remove 99%+ of all dust and debris from even hard to reach areas without damaging items.

Air Knife Systems Benefits for Beverage Production Lines

Air Knife Systems provide a full range of benefits for beverage production lines, including:

- Drys bottles, cans & jars

- Dries beverage crates & trays

- Removes moisture prior to coding or labelling

- Meets food hygiene standards

- After washing or rinsing – preventing both corrosion & bacteria

- Oil-free clean air

- Surface moisture completely removed

- Static eliminated

- Dust removal from final packaging

See typical products & use-case applications

Increase production & reduce costs

Air Knife Systems provide ionised air, removing water and static from bottles, cans and jars. This means full cleaning prior to coding, labelling and packaging – eliminating spoiled goods through moisture damage or incorrect finishing.

A SolvAir Air Knife will generate cost savings, speed up operations and/or provide other improvements in the manufacturing process. In many cases, assembly and conveyor line speeds have been increased by as much as 50% due to the efficiency of a SolvAir Air Knife.

Investment paybacks are often achieved in just a few months, sometimes in a matter of weeks, providing a superior return-on-investment.

Contact us to discuss your specfic requirements