Can Drying Systems

Cans are one of the most important packaging products in the world today. For example, the global market for metal cans is currently estimated to be valued at USD 27.6 billion in 2020 - and it is projected to reach USD 37.0 billion by 2025.1

Used for key applications such as drying, cleaning, blow-off, and preparation of cans for labelling and other coding such as date stamps Can Drying Systems are key to the food and beverage manufacturing process.

Industrial Can Drying

Drying is one of the most important requirements for the food and beverage production line process for cans. Cans are exposed to moisture in many different ways, from washing to filling to condensation in the production environment. Industrial Can Drying Systems are also able to remove dust and debris from the surface of cans, which is essential to ensure quality control measures are met.

Failure to mitigate debris from the surface of cans, and failure to fully remove moisture or dust, has significant and negative financial consequences for food and beverage companies.

Drying Systems for Cans & Beverage Containers - the Benefits

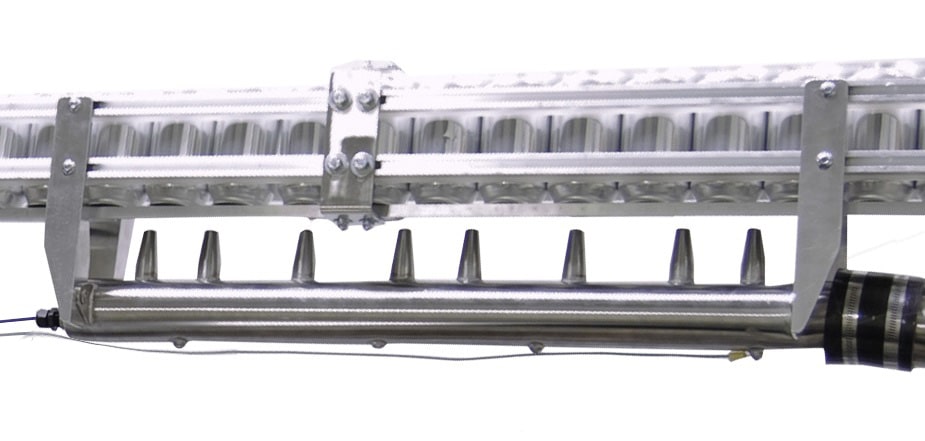

Our Can Drying Systems are Air Knife drying systems designed and engineered to create air jets that effectively remove 99%+ of moisture and debris from cans as part of the production process.

They ensure that no cans remain wet along the production line, meaning the potential for rust and corrosion damage is minimised, as well as the potential for products to be rejected as a result of inaccurate labelling or poor appearance.

Our Can Drying Systems also improve the speed of the production line, minimising disruption from damaged items, as well as creating a hygienic environment for can processing that meets quality control standards.

Air Knife Drying Systems for Can Drying

Air Knife Drying Systems are highly effective, energy-efficient drying systems capable of high performance can drying. Air Knife Drying Systems have air blades or nozzles positioned on a conveyor belt to target all areas of a can’s surface, and are linked to high speed energy-efficient Air Blowers to create a high-velocity air jet to dry, clean and blow-off cans as they move along the line.

Air Knife Drying Systems for can drying are easy to install, low-maintenance, space-efficient, providing reliable performance. They also generate cost savings through low energy usage, improve the overall quality of finished products, and minimise disruption occurring when cans are not fully dried.

Aluminium Can Drying Systems

Aluminium cans have been rising in prominence with food and beverage production companies as they have been shown to contribute to less waste polluting the oceans than plastic bottles.

However, working with aluminium does mean a potential increase in carbon footprint, and so companies have been looking for ways to mitigate this. Air Knife Drying Systems, when combined with efficient centrifugal blowers offer much lower energy usage and substantial energy savings when compared to compressed air drying systems.

Ionizing Air Can Rinser

Air Knife Drying Systems for Cans are being updated year on year to improve their benefits for the food and beverage industry.

For example, we now offer an ionized air can rinser system that is able to rinse cans following the cleaning/filling process, but without water.

This means less maintenance, less potential for object moisture damage, and less costs overall.